Pro'sKit SS-331H ESD LCD Digital Electric Desoldering Pump 220V - Suction Vacuum Solder Sucker

0 out of 5 stars

No review yetOut of stock

NaN

As low as NaN

Worldwide shipping

Seller: Worldswa Shenzhen

ID: MV-2112099P27US

Weight: 3.00 kg

| Qty | Price | Discount |

|---|---|---|

| 1 | NaN | |

| 3 | NaN | -3.2% |

| 5 | NaN | -4.8% |

| 10 | NaN | -7.1% |

Extra Adapter

Choose a Extra Adapter

AUEUUKUS

Product details

Description

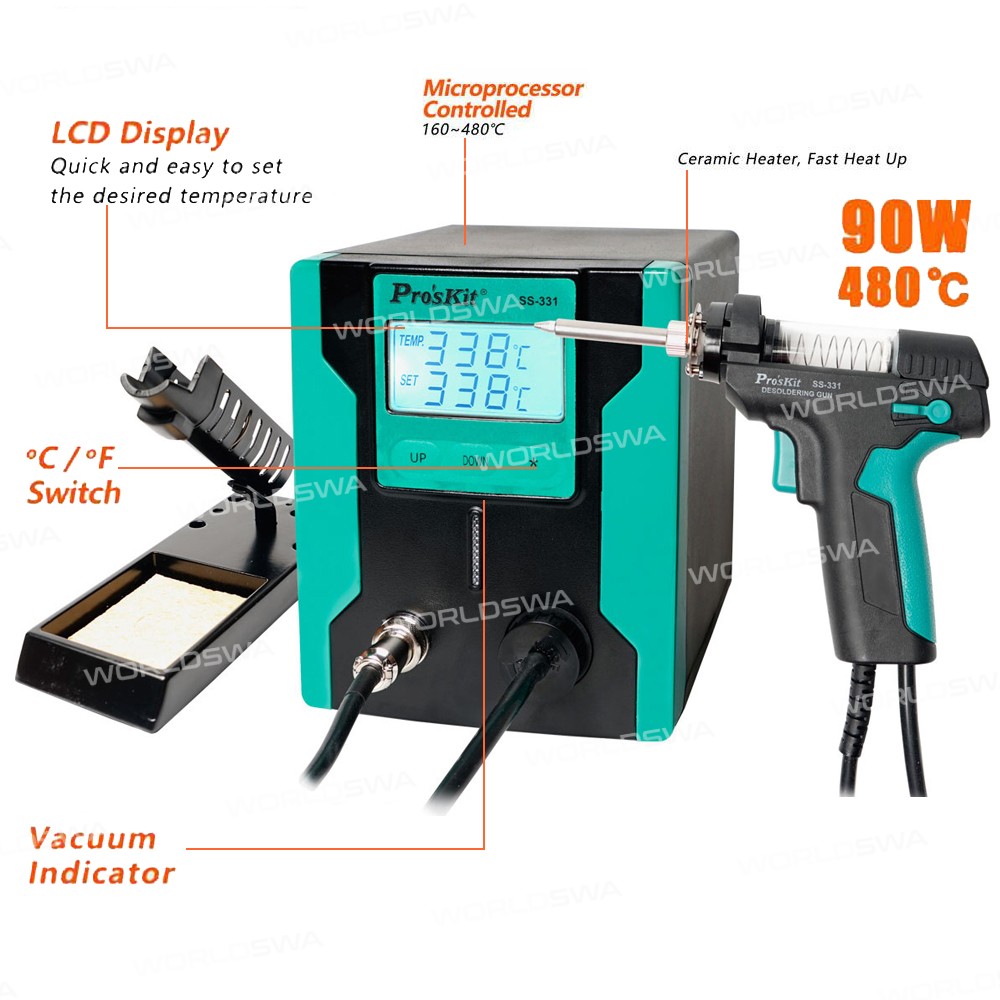

Pro'sKit SS-331H ESD LCD Digital Electric Desoldering Pump with Suction Vacuum Solder Sucker

Features:

- Intelligent control + strong suction + high efficiency, saving time and worry.

- Suitable for large-scale disassembly of integrated circuit boards in factory assembly lines, repair shops, etc., to improve work efficiency.

- Precision design, automatic control, precise temperature control of 160-480℃.

- Using high-efficiency ceramic, heating up quickly.

- The LCD screen can quickly set the temperature and easily control the status.

- Transparent solder bath, tin dross can be seen and cleaned more easily.

- Stainless steel through needles, equipped with 3 kinds of diameter stainless steel through needles, select the suitable through the needle to clean the nozzle hole.

- Summary:** Efficient, precise, and easy to use desoldering pump with advanced features.

Specification:

- Model: SS-331H

- Voltage: AC 240V

- Power: 90W

- Power Consumption: 140W

- Temperature: 160℃--480℃

- Control System: Microprocessor

- Vacuum Pump System: Air Pump Motor

- Vacuum Suction: >600mm Hg

- Insulation Resistance:100MΩ

- Ground Resistance:0.3Ω

- Heating Principle: Ceramic Heating

- Tube Length:105cm

- Power Cable Length: 1.2M (3 core cord ground plug)

- Size: 172*135*190MM

Package includes:

- 1 x Pro'sKit SS-331H

- 1 x Power Cable

- 3 x Nozzles

Notes:

- After Each Use. It is recommended to take 3-5 times Empty Suction to Full Clear the residual Tin in The Tube

- If the interval is about 20 minutes, it is recommended to use a needle to clean the steel pipe after emptying the suction

- During the use, If the suction is reduced. Please use a needle to clean the steel pipe

- If you do not use it often, it is recommended to adjust the tin gun to about 200 degrees, and then adjust to the working temperature when using it

- When there is about 1/2 of the tin slag in tin storage. It should be cleaned in time. When the filter Spong is hard, Pls replace it in time

Customer reviews

0.0/ 5.0

0

0

0

0

0